Cutting Edge: Navigating the Specialty Gas Market in 2025 with Metro Welding Supply

Discover how Metro Welding Supply Corporation is delivering precision, sustainability, and unmatched reliability in the evolving specialty gas market.

As a cornerstone of the specialty gas industry since 1937, Metro Welding Supply Corporation combines decades of expertise with innovative solutions to meet the ever-evolving demands of our clients. From high-pressure cylinders to micro-bulk and bulk gas solutions, our operations are built on precision, reliability, and sustainability. By following ISO 17025 standards and employing advanced tracking systems like TrakAbout, we ensure top-tier service while navigating the dynamic landscape of 2025.

The Evolution of Specialty Gases in Industry

Industries such as medical, manufacturing, and food services are increasingly reliant on advanced specialty gas solutions. This evolution has brought about significant changes in gas composition, delivery methods, and quality assurance practices. Each development has pushed the boundaries of what gases can achieve, emphasizing efficiency and precision in operations.

Shifts in Laser Cutting Technology

The laser cutting industry, a significant user of specialty gases, has seen a transition from CO2 lasers to fiber lasers. This shift has influenced gas demand:

- CO2 Lasers: Historically dominant, requiring oxygen and nitrogen for cutting precision. Their consistent results have cemented their place in manufacturing for decades.

- Fiber Lasers: More energy-efficient and precise, requiring high-purity nitrogen and occasional blends with argon for shielding purposes. These innovations have paved the way for faster and cleaner cuts, particularly with reflective metals.

For companies like Metro Welding, this evolution means scaling up high-purity gas production and offering tailored solutions that match industry requirements.

Gases Driving Innovation

Key gases shaping industry practices include:

- Nitrogen: Vital for shielding and oxidation prevention in cutting and welding applications, ensuring clean and reliable results.

- Oxygen: Supports combustion and enhances cutting speed for steel, boosting operational throughput.

- Argon: Used in inert environments for welding and laser applications, contributing to precision and safety in specialized tasks.

By offering certified pure gases and custom blends, Metro Welding ensures optimal performance and compliance with ISO 17025 standards for testing and calibration.

Precision and Reliability with TrakAbout

Managing an extensive inventory of gas cylinders requires advanced tools, and TrakAbout has become an integral part of our operations. This cylinder tracking system provides complete visibility into our supply chain, ensuring precision and efficiency. Such technology helps Metro Welding maintain its reputation for reliability in a competitive market.

Benefits of TrakAbout:

- Comprehensive Tracking:

- Real-time monitoring of cylinder distribution, usage, and maintenance history, eliminating logistical blind spots.

- Reduced losses due to theft or misplacement, ensuring cost-effective operations.

- Enhanced Customer Experience:

- Transparent billing based on accurate usage data, offering clarity and trust.

- Clients can access details about delivery schedules and cylinder history to plan effectively.

- Safety and Compliance:

- Automated reminders for maintenance and recertification to enhance safety protocols.

- Adherence to regulatory requirements, minimizing safety risks and ensuring smooth audits.

- Operational Efficiency:

- Optimized delivery routes, reducing fuel consumption and environmental impact.

- Improved inventory management with just-in-time delivery strategies, streamlining client supply chains.

By integrating TrakAbout with our ERP systems, Metro Welding simplifies logistics and ensures a seamless customer experience.

ISO 17025: Setting the Benchmark for Quality

Adhering to ISO 17025 regulations ensures our testing and calibration methods meet international standards. This commitment provides clients with confidence in the reliability and accuracy of our gas products, fostering trust and long-term partnerships.

Key Elements of ISO 17025 Compliance:

- Rigorous Quality Control:

- Regular testing of gas purity with state-of-the-art equipment to uphold industry-leading standards.

- Certification of analysis for each cylinder, ensuring traceability and accountability.

- Continuous Improvement:

- Training programs for technicians to stay updated on best practices and emerging technologies.

- Routine audits to identify and address gaps in processes, enhancing efficiency.

- Client Benefits:

- Assurance of consistent gas quality, essential for high-stakes industries like healthcare and aerospace.

- Confidence in meeting industry-specific regulatory standards, reducing compliance risks.

Sustainability: A Practical Approach

Sustainability is at the heart of Metro Welding’s operations. From reducing waste to minimizing our carbon footprint, we implement environmentally responsible practices across the board. This commitment underscores our role as a responsible industry leader.

Sustainable Initiatives:

- Cylinder Management and Recycling:

- Tracking cylinder lifecycles to maximize reuse and minimize waste, ensuring sustainable inventory practices.

- Partnering with vendors that prioritize eco-friendly materials and practices in cylinder production.

- Gas Efficiency:

- Educating clients on proper flow rates and gas mixtures, improving operational accuracy.

- Offering guidance on the efficient use of gases to reduce waste and lower costs.

- Streamlined Deliveries:

- Optimizing delivery schedules and routes to reduce emissions and enhance reliability.

- Implementing delivery systems that minimize downtime and ensure consistent supply.

By fostering sustainable partnerships and focusing on operational efficiency, Metro Welding ensures long-term benefits for clients and the environment.

Expanding Educational Support for Clients

Metro Welding Supply understands that informed clients can maximize the value of our services. That’s why we’ve developed comprehensive educational programs tailored to the needs of each industry we serve. Our efforts aim to empower businesses with knowledge that enhances operational efficiency and safety.

- Workshops and Training:

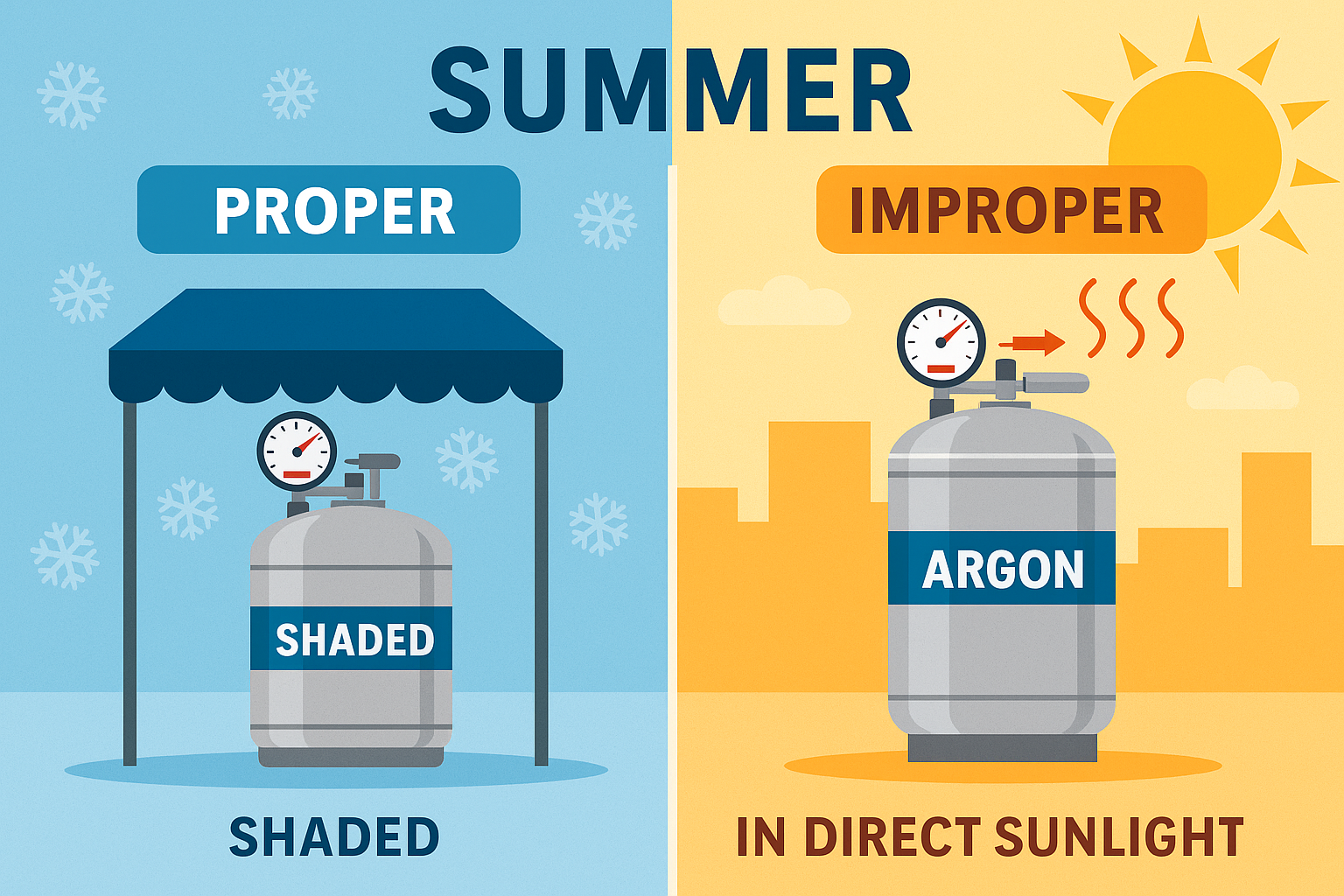

- Hands-on demonstrations for proper gas handling and storage, ensuring safe and effective use.

- Guidance on how to maintain equipment to prolong its life and optimize performance.

- Digital Resources:

- Online guides and videos to support client learning at their convenience, ensuring accessibility. (coming soon!)

- Regularly updated blog and social media posts covering industry trends, operational tips, and emerging challenges.

- Customized Consultations:

- One-on-one consultations to address unique client challenges, fostering personalized solutions.

- Site assessments to identify inefficiencies and recommend tailored strategies for improvement.

- Regulatory Support:

- Assisting clients in meeting their compliance requirements with high-quality, certified gases.

- Guidance on documentation and best practices to navigate industry regulations effectively.

Supporting Industry Needs with Practical Solutions

Metro Welding Supply focuses on providing solutions that align with the immediate and long-term needs of our clients. By understanding industry demands, we tailor our offerings to enhance productivity and safety.

- Partnerships with Clients:

- Collaborating directly with businesses to understand their specific requirements and deliver customized solutions.

- Offering flexible delivery schedules and inventory options to adapt to changing operational needs.

- Focus on Quality Assurance:

- Ensuring every cylinder is thoroughly tested and certified for its intended use.

- Maintaining rigorous quality control protocols to meet and exceed client expectations.

- Responsive Customer Service:

- Providing dedicated support teams to address inquiries and offer technical assistance.

- Offering 24/7 support for critical supply needs to ensure uninterrupted operations.

Meeting Future Challenges with Innovation

As the market evolves, Metro Welding Supply Corporation continues to position itself as a leader by anticipating trends and adapting to client needs. Key areas of focus include:

- Advanced Applications:

- Supporting industries like aerospace and healthcare with ultra-high-purity gases, meeting specialized demands.

- Customizing gas solutions to meet the exacting standards of advanced manufacturing and research.

- Digital Integration:

- Utilizing tracking systems like TrakAbout to maintain visibility and efficiency in cylinder management.

- Offering clients data-driven insights to improve supply chain management and forecast needs accurately.

- Client-Centric Solutions:

- Expanding micro-bulk and bulk delivery options to accommodate growing operational needs.

- Providing emergency support to address urgent supply requirements, prioritizing client satisfaction.

Why Choose Metro Welding Supply?

Metro Welding’s legacy of excellence, combined with modern technology and a client-first approach, sets us apart in the specialty gas market. By adhering to ISO 17025 standards and utilizing tools like TrakAbout, we deliver unmatched quality, safety, and reliability.

Our Promise:

- Accuracy: Every cylinder tested and certified for purity.

- Efficiency: Streamlined operations reduce costs and lead times.

- Sustainability: Committed to eco-friendly practices and innovation.

Enhance your laser cutting operations with premium specialty gases from Metro Welding Supply.

Contact us today for expert solutions or to

request a quote tailored to your industry needs!

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660