How Michigan’s Legal Cannabis Industry Relies on Specialty Gases for Growth

From extraction to preservation, specialty gases like CO2 and nitrogen play a crucial role in Michigan’s thriving cannabis industry. Discover how these essential gases optimize production, extend shelf life, and ensure compliance for growers, processors, and dispensaries alike.

The High Demand for High-Quality Gases

Michigan’s cannabis industry is thriving, with dispensaries, cultivation centers, and extraction labs expanding rapidly. Whether you're a grower, processor, or dispensary owner, the use of specialty gases plays a critical role in extraction, preservation, and cultivation.

At Metro Welding Supply, we provide high-purity gases that help cannabis businesses improve efficiency, maintain product quality, and stay compliant with regulations.

So, how do CO2, nitrogen, and other specialty gases fuel Michigan’s booming cannabis industry? Let’s dive in.

CO2 Extraction: The Gold Standard for Cannabis Oil Production

One of the most popular and efficient methods of extracting cannabis oils and concentrates is supercritical CO2 extraction. This method is preferred because it:

✅

Produces High-Purity Extracts – CO2 extraction yields clean, solvent-free cannabis oil that is safe for consumers.

✅

Is Environmentally Friendly – Unlike chemical solvents, CO2 is non-toxic and leaves no harmful residues.

✅

Allows for Precision Control – Operators can fine-tune pressure and temperature to isolate specific cannabinoids and terpenes.

✅

Meets Industry Regulations – CO2 is GRAS (Generally Recognized as Safe) by the FDA, making it a preferred solvent for cannabis extraction.

Beyond purity and efficiency, CO2 extraction is also safer than hydrocarbon-based extraction methods, such as butane or propane, which carry higher risks of explosions and chemical contamination. This makes CO2 the best choice for cannabis processors seeking to meet Michigan’s strict safety and environmental regulations. Another advantage of supercritical CO2 extraction is that it allows producers to adjust the solubility of compounds by varying pressure and temperature, which enables selective extraction of cannabinoids like THC and CBD. This precision leads to customized product formulations that cater to medical and recreational cannabis consumers.

🔹 Metro Welding Supply offers high-purity CO2 in bulk and cylinder form, ensuring cannabis processors always have a reliable supply. Learn more about our CO2 solutions.

Nitrogen: Extending the Shelf Life of Cannabis Products

Nitrogen (N₂) is widely used in the food and beverage industry to prevent oxidation—and the same applies to cannabis. Nitrogen gas helps preserve cannabis flower, edibles, and extracts by eliminating oxygen exposure.

🔹 How does nitrogen benefit cannabis packaging?

✅

Prevents Oxidation – Oxygen exposure degrades cannabinoids and terpenes, reducing product potency and freshness.

✅

Extends Shelf Life – Nitrogen flushes out oxygen before sealing packages, keeping cannabis fresh for longer.

✅

Enhances Product Quality – By reducing moisture buildup, nitrogen prevents mold and microbial growth.

Nitrogen is also widely used for vacuum-sealed packaging, which extends the shelf life of cannabis products without the need for chemical preservatives. Growers and manufacturers can use nitrogen flushing to replace oxygen inside cannabis packaging, preventing cannabinoid degradation caused by exposure to light, heat, and air. Additionally, nitrogen helps prevent static charge buildup in cannabis processing environments, reducing the risk of contamination from dust particles. Nitrogen is also essential in cannabis freeze-drying processes, where it maintains freshness without altering the potency of THC or CBD. Michigan’s cannabis companies can benefit significantly by incorporating nitrogen into their packaging, storage, and processing workflows.

💨 Metro Welding Supply provides food-grade nitrogen solutions for cannabis processors and packagers. Discover our nitrogen gas offerings.

Humidity Control: Creating the Perfect Environment for Cannabis Cultivation

Growers know that humidity control is key to producing high-quality cannabis flowers. Too much or too little humidity can affect terpene profiles, cannabinoid content, and overall plant health.

🔹 How can specialty gases help?

✅

CO2 Enrichment – Raising CO2 levels in grow rooms can increase plant growth rates and boost yields.

✅

Humidity Regulation – Dry nitrogen can be used to control moisture levels and prevent mold outbreaks.

✅

Consistent Environmental Conditions – Specialty gases ensure a stable grow room climate, leading to higher potency cannabis.

Maintaining optimal humidity levels (typically 55-65% RH) is essential for preventing mold and mildew while ensuring strong plant growth. If humidity levels drop too low, cannabis plants experience water stress, which can negatively impact resin production and lower THC and CBD levels. On the other hand, excessive humidity can cause bud rot and fungal infections, leading to product loss. CO2 supplementation is another critical factor, as increasing CO2 levels from 400 ppm to 1,200 ppm can boost photosynthesis efficiency by up to 50%. This results in denser, more resinous flowers, making CO2 a must-have for high-yield cannabis operations.

🌱 Metro Welding Supply offers CO2 and nitrogen gas solutions tailored for Michigan cannabis cultivators. Explore our specialty gas solutions.

Bulk vs. Cylinder Gas: Which is Best for Your Cannabis Business?

When choosing a gas supply option, cannabis businesses must consider efficiency, storage space, and cost.

Cylinder Gas (High-Pressure Tanks

✔️ Best for small-scale extraction and packaging operations

✔️ Requires

frequent refills but takes up

less space

✔️ Ideal for

new cannabis businesses or those with

lower gas usage

Micro-Bulk & Bulk Gas Systems

✔️ Best for large-scale cannabis cultivation and processing

✔️ Provides

continuous gas supply with

fewer deliveries

✔️ Reduces long-term costs and

improves efficiency

For high-production extraction labs and large-scale cannabis cultivation facilities, micro-bulk or bulk gas systems are the most efficient option. These systems reduce downtime caused by cylinder changes, eliminate waste from returned gas, and provide consistent supply pressure for large operations. Bulk gas systems also reduce logistics costs, as fewer deliveries are needed compared to individual cylinders. For smaller businesses, cylinders are an ideal solution due to their lower upfront costs and ease of storage. Metro Welding Supply offers customized bulk and micro-bulk gas solutions to match the specific needs of Michigan’s cannabis industry.

💡 Metro Welding Supply offers customized gas delivery solutions, including cylinder rentals, micro-bulk, and bulk gas systems for cannabis businesses. Learn about our microbulk gas solutions.

Regulatory Compliance: Safe Handling & Storage of Gases

Michigan’s cannabis industry is highly regulated, and proper gas handling is essential for compliance and safety. Businesses must follow strict storage and ventilation guidelines for gases like CO2, nitrogen, and butane.

🔹 Key safety considerations:

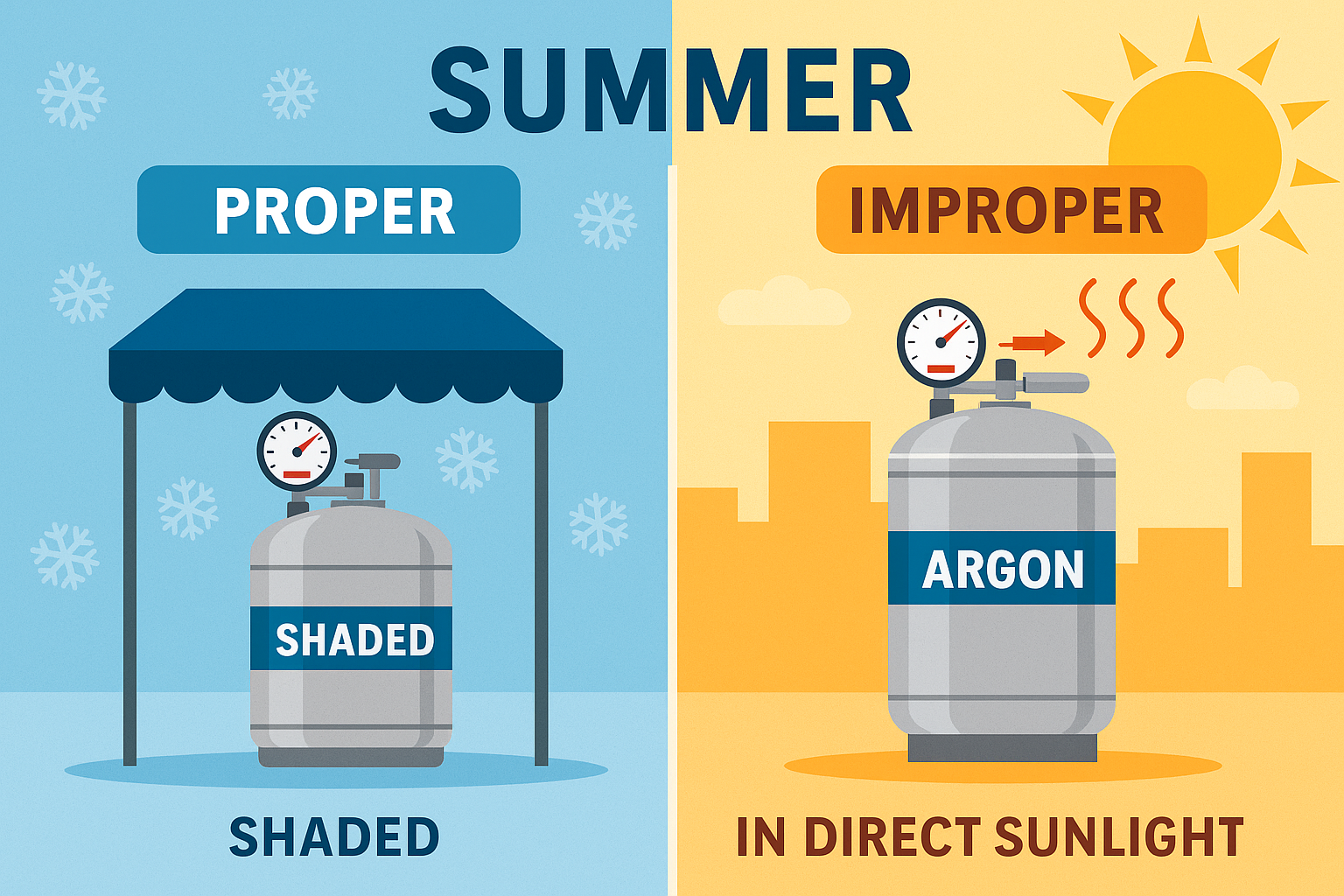

✔️ Store gas cylinders upright and in a ventilated area

✔️ Use proper regulators to prevent over-pressurization

✔️ Implement gas leak detection systems for safety compliance

✔️ Follow OSHA and Michigan Cannabis Regulatory Agency (CRA) guidelines

The Michigan Cannabis Regulatory Agency (CRA) has strict guidelines for gas storage and handling in cannabis production facilities. Businesses using CO2 extraction must ensure proper ventilation and leak detection to prevent hazardous buildup in enclosed spaces. Butane and propane extraction labs must follow Class 1 Division 1 explosion-proof safety standards, requiring proper fire suppression and airflow systems. For cannabis greenhouses, using CO2 enrichment comes with monitoring requirements to prevent excess CO2 accumulation, which could harm workers. Metro Welding Supply helps cannabis businesses stay compliant with OSHA and CRA regulations, ensuring safe gas handling and storage.

🏢 Metro Welding Supply provides safety consultations and gas handling training to keep your business compliant.

Why Choose Metro Welding Supply?

Metro Welding Supply is a trusted provider of specialty gases to Michigan’s cannabis industry. Whether you're a grower, extractor, or packaging facility, we provide:

✔️

High-purity CO2, nitrogen, and specialty gases

✔️

Bulk gas delivery for large-scale cannabis production

✔️

Compliance and safety training for handling compressed gases

✔️

Custom gas solutions tailored to your business needs

🌱 Let’s Grow Together! Contact Metro Welding Supply today for a free consultation on the best gas solutions for your cannabis business.

📞

Call us at 313-841-1660

📍

Visit us at www.metrowelding.com

Final Thoughts

The legal cannabis industry in Michigan depends on high-quality gases for extraction, preservation, and cultivation. Whether you’re scaling production, optimizing packaging, or improving grow operations, Metro Welding Supply provides the specialty gases you need to keep your business running efficiently.

🔥 Don’t let gas shortages slow your cannabis operation. Contact us today for expert guidance and reliable gas supply solutions!

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660