How Restaurants & Breweries Can Optimize Their CO2 Supply for Patio Season

With patio season rapidly approaching, restaurants and breweries face increased demand for perfectly carbonated beverages. Learn how to optimize your CO2 supply, prevent costly shortages, and keep your customers coming back for crisp, refreshing drinks all season long.

Maximizing CO2 Efficiency for Peak Patio Season

As temperatures rise and patio season kicks into full swing, restaurants, bars, and breweries experience a surge in beverage sales. With outdoor dining areas expanding, the demand for cold, refreshing, and perfectly carbonated drinks reaches its peak. Whether serving draft beer, sodas, sparkling water, or carbonated cocktails, having a reliable CO2 supply is essential for maintaining high beverage quality, smooth operations, and customer satisfaction.

One of the biggest challenges businesses face during this time is underestimating CO2 consumption, which can lead to mid-shift shortages, service delays, and product waste. Managing CO2 supply efficiently not only ensures a consistent pour but also reduces costs associated with emergency refills and lost products. Without a steady and properly regulated CO2 source, drinks can become flat, over-foamed, or lose their intended flavor, directly impacting the customer experience.

Additionally, as the competition among bars and breweries increases, customer expectations for quality beverages continue to rise. Whether it’s craft beer lovers expecting the perfect head on their IPA or cocktail enthusiasts looking for crisp carbonation in their spritzers, consistent CO2 pressure and purity are critical for meeting consumer demands.

At Metro Welding Supply, we specialize in providing food-grade CO2 solutions to keep your beverages perfectly carbonated and your business running smoothly. Our bulk CO2 supply, micro-bulk solutions, and scheduled refills ensure that your establishment never runs out of CO2 during peak service hours.

This article will walk restaurant and brewery owners through the best practices for optimizing their CO2 supply, preventing costly downtime, and avoiding common carbonation issues during the busiest outdoor dining season of the year.

How to Calculate CO2 Needs for Increased Beverage Sales

During patio season, demand for carbonated beverages spikes. Whether you run a brewpub, sports bar, or fine dining restaurant, accurately estimating CO2 needs ensures you never run out during peak hours.

🔹 How Much CO2 Does Your Business Need?

✔️

Draft Beer: 1 lb of CO2 dispenses ~4-8 gallons of beer

✔️

Soda Machines: 1 lb of CO2 dispenses ~6-10 gallons of soda

✔️

Carbonated Cocktails: Varies based on the system setup but requires stable pressure

To properly estimate your CO2 usage, track your weekly beverage sales trends and plan for high-volume events, such as happy hours, live music nights, and weekend brunches. If your business has multiple draft lines, ensure you calculate the total CO2 demand across all kegs and soda dispensers.

Businesses serving high-turnover drinks like craft beer should also factor in line cleaning schedules, which require additional CO2 usage. Investing in a digital CO2 monitoring system can provide real-time consumption data to prevent unexpected shortages.

💡 Pro Tip: Avoid costly emergency refills by scheduling CO2 deliveries in advance with Metro Welding Supply’s automatic restocking program.

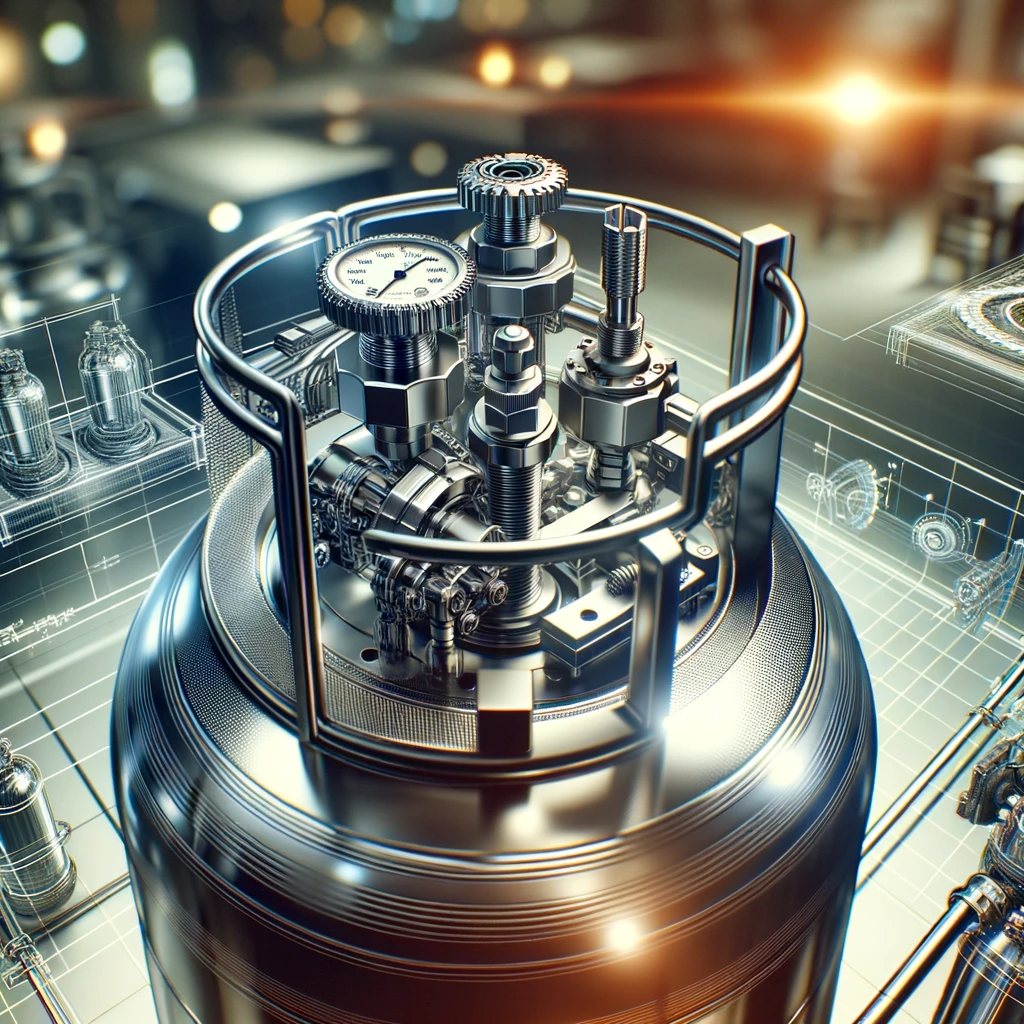

The Advantages of Bulk CO2 Systems Over Traditional Cylinders

Many restaurants and breweries start with individual CO2 cylinders, but as demand increases, upgrading to a bulk CO2 system delivers greater efficiency and cost savings.

🔹 Why Upgrade to Bulk CO2?

✅

Fewer Refills & Deliveries – Eliminates frequent cylinder swaps

✅

Consistent CO2 Supply – Reduces risk of running out during peak hours

✅

Lower Operating Costs – Bulk purchasing reduces per-unit gas expenses

✅

Enhanced Safety – Minimizes heavy cylinder handling and potential leaks

Unlike traditional cylinders, bulk CO2 systems store liquefied carbon dioxide in larger tanks, providing a continuous supply directly to your beverage dispensers. This eliminates downtime caused by cylinder changes, prevents pressure fluctuations, and allows for precise CO2 regulation across multiple draft lines.

Additionally, bulk CO2 systems require less storage space than managing multiple tanks, improving the workflow behind the bar. With automatic refill scheduling, restaurants and breweries never have to worry about running out of CO2 on busiest nights.

💡 Pro Tip: Businesses using more than 10 CO2 cylinders per month can save time and money by switching to a bulk CO2 system. Contact Metro Welding Supply for custom solutions.

How to Prevent Foam and Flat Beer Issues

Serving a perfectly carbonated beer is an art and science. Foamy beer or flat drinks can frustrate both bartenders and customers, leading to waste and lost revenue.

🔹 Best Practices for Maintaining Proper Carbonation:

✔️

Adjust CO2 Pressure Based on Beer Type – Lagers require 10-14 PSI, while nitrogen-infused stouts need 30-40 PSI

✔️

Maintain Proper Keg Temperatures – Draft beer should be kept between

36-38°F for optimal carbonation

✔️

Inspect CO2 Lines for Leaks – Even small leaks

disrupt pressure consistency, leading to

pour issues

✔️

Use Food-Grade CO2 – Non-food-grade CO2 can introduce unwanted

odors or flavors into beverages

Flat beer is often caused by low CO2 pressure, while excessive foaming results from over-carbonation, warm kegs, or improper pressure settings. Ensure that beer lines are properly balanced, with the right CO2-to-keg ratio to maintain consistent pours.

Investing in CO2 pressure regulators and digital monitoring systems helps bartenders quickly adjust gas flow, reducing the likelihood of wasted beer or inconsistent drinks.

💡 Pro Tip: Implementing a CO2 tank monitoring system ensures stable gas levels for consistent beverage quality. Metro Welding Supply provides food-grade CO2 and expert system support.

Understanding Food-Grade Gases for Beverage and Food Preservation

CO2 isn’t just essential for beer and soda—it plays a vital role in food preservation and packaging. Restaurants and breweries use food-grade CO2 and nitrogen for:

🔹 Common Food-Grade Gas Applications:

✔️

Draft Beer Dispensing – Ensures optimal carbonation and reduces oxidation

✔️

Soda & Soft Drinks – Maintains crisp flavor and carbonation consistency

✔️

Nitro Cold Brew & Cocktails – Uses nitrogen gas for smooth texture and enhanced presentation

✔️

Modified Atmosphere Packaging (MAP) – Extends shelf life of pre-packaged foods

Using certified food-grade CO2 ensures beverages remain free from impurities and comply with food safety standards. Cheaper, non-certified CO2 sources may contain contaminants that affect drink taste and quality.

💡 Pro Tip: If your business uses CO2 for multiple applications, bundling food-grade CO2 and nitrogen can save money and streamline operations. Metro Welding Supply offers customized gas solutions for the food & beverage industry.

How Metro Welding Supply Ensures a Steady Supply of CO2

At Metro Welding Supply, we know that a reliable CO2 supply is essential for restaurants and breweries, especially during peak patio season.

That’s why we offer:

✔️ Scheduled CO2 Deliveries –

Ensures a steady gas supply with no last-minute shortages

✔️ Bulk & Micro-Bulk CO2 Systems –

Customizable options to fit any business size

✔️ Food-Grade Gas Certification –

100% pure, contaminant-free CO2 for beverages

✔️ CO2 System Maintenance & Support –

Expert assistance to keep your draft system running smoothly

With local CO2 supply chains and on-time delivery services, Metro Welding Supply ensures your business stays fully stocked with high-quality beverage-grade CO2 all season long.

📞 Call us at

313-841-1660 to set up a CO2 delivery plan for your restaurant or brewery.

📍 Visit us at www.metrowelding.com to request a free quote!

Final Thoughts

As outdoor dining and patio seating expand in the spring, businesses must optimize CO2 supply to meet increased demand, maintain drink quality, and prevent service disruptions. Switching to bulk CO2, monitoring pressure settings, and using food-grade gases ensures that every pour is perfect.

🔥 Don’t wait for a CO2 emergency—contact Metro Welding Supply today to secure your gas supply and keep your beverages flowing!

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660

Agency Contact Form

More Industry Tips, Tricks & Tools...

Industry Insights (i2)