The Role of Micro-Bulk Gases in Sustainable Welding: Top Welding Equipment Maintenance Tips for Metro Welding Supply Corporation

Learn about the role of micro-bulk gases in sustainable welding and discover top welding equipment maintenance tips for Metro Welding Supply Corporation.

Welding, an essential process in multiple industries such as construction, manufacturing, and medical equipment production, relies heavily on gases to create optimal conditions for metal fusion. Among the most recent advancements in the industry is the growing use of micro-bulk gases, which have begun to revolutionize welding practices by offering more sustainable, efficient, and cost-effective solutions. In this article, we'll dive deep into the role that micro-bulk gases play in sustainable welding and provide essential tips for maintaining welding equipment to ensure maximum performance.

Introduction to Micro-Bulk Gases and Their Importance in Welding

What Are Micro-Bulk Gases?

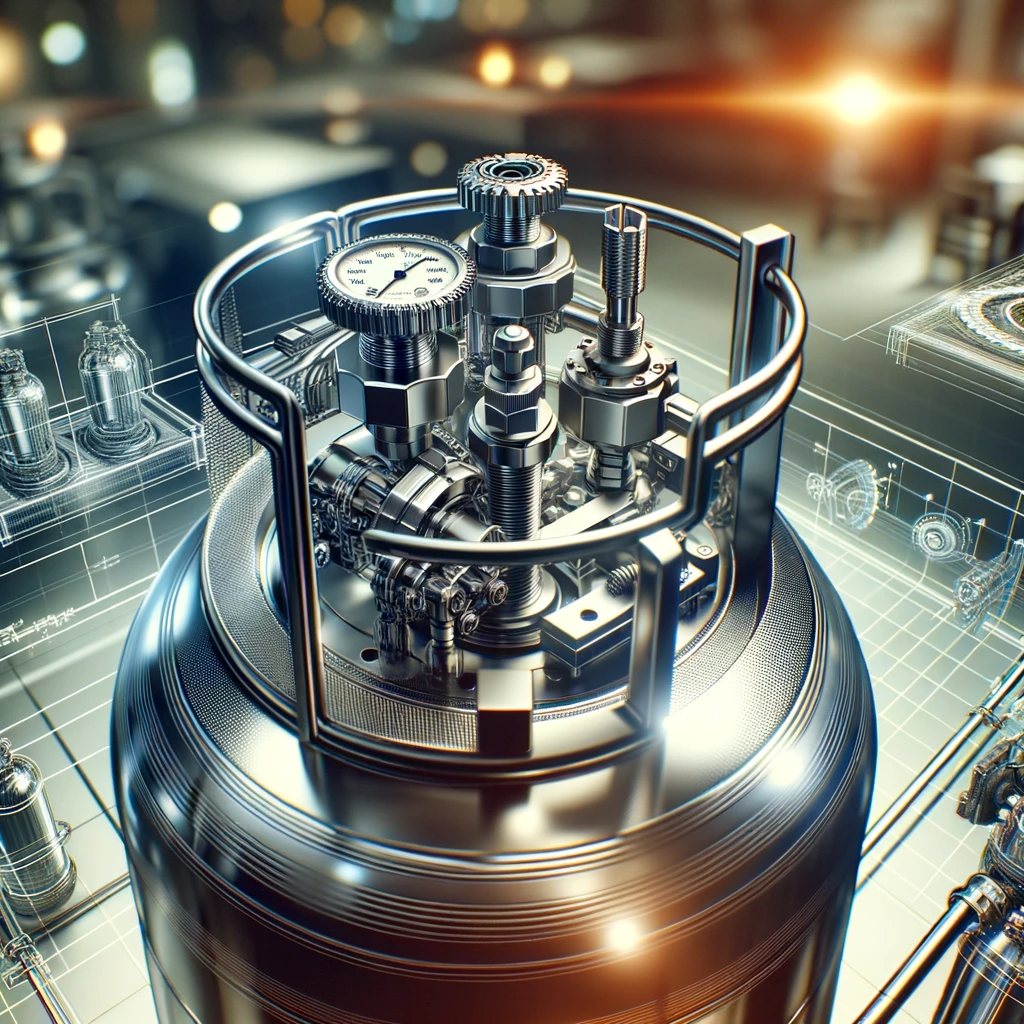

Micro-bulk gases refer to a type of gas supply system that involves the delivery of gases in larger quantities than traditional cylinders but in smaller amounts than bulk storage systems. These gases are stored in tanks that are either onsite at the welding facility or delivered on-demand for use in various industrial applications. Unlike conventional cylinder gas systems, micro-bulk gas systems are easier to handle and more scalable, making them ideal for businesses that require continuous gas supply but don't need the large-scale infrastructure of bulk systems.

The Role of Micro-Bulk Gases in Industrial Welding Applications

Micro-bulk gases play a critical role in welding by providing consistent and reliable gas supply for the welding processes. Common gases like argon, carbon dioxide (CO2), and oxygen are used in a range of welding applications such as MIG welding, TIG welding, and flux-cored arc welding (FCAW). These gases act as shielding agents, preventing contamination of the weld pool, which can significantly affect the quality of the weld.

Key Benefits of Using Micro-Bulk Gases in Welding

- Consistent gas supply: Micro-bulk systems ensure that your welding operations have a continuous and reliable gas supply, minimizing downtime due to empty cylinders.

- Space and storage efficiency: Unlike bulky cylinder systems, micro-bulk tanks are compact and can be easily integrated into a variety of welding environments.

- Cost savings: Purchasing gases in bulk through a micro-bulk system can offer significant savings in comparison to the cost of individual gas cylinders.

Why Sustainability is Critical in Welding Industries

Environmental Impact of Welding Practices

Welding operations, particularly those in heavy industries, can have a significant environmental impact. The use of gases such as CO2 in large quantities can contribute to greenhouse gas emissions, and the disposal of gas cylinders can create waste that ends up in landfills. Sustainable welding practices are necessary to reduce these negative effects while ensuring high-quality, durable results.

How Micro-Bulk Gases Contribute to Sustainable Welding

Micro-bulk gases are part of the solution to creating more sustainable welding practices. The delivery systems allow businesses to reduce the overall carbon footprint by minimizing the waste produced from individual gas cylinders. The compact and more efficient gas delivery also reduces the energy required to transport and store gases, making the process more environmentally friendly.

Advantages of Micro-Bulk Gases Over Traditional Cylinder Gases

Cost Efficiency

With micro-bulk gases, businesses are able to purchase gases in larger quantities at a lower cost per unit. This cost-effectiveness is passed along to the customers, allowing them to reduce overhead expenses while maintaining the same high-quality results.

Reduced Environmental Footprint

Micro-bulk systems cut down on packaging and transportation waste. Traditional cylinder systems often require frequent deliveries, resulting in more fuel usage and emissions. By switching to a micro-bulk system, welding operations can significantly reduce their environmental footprint.

Improved Welding Performance

Micro-bulk gas systems offer more control over the flow rate and purity of the gases used in welding, which can directly influence the quality and consistency of the weld. This translates to fewer defects and better welds over time, contributing to overall operational efficiency.

How to Integrate Micro-Bulk Gases into Your Welding Operations

Choosing the Right Micro-Bulk Gases for Your Welding Needs

The first step in integrating micro-bulk gases is determining which gases are best suited to your welding operations. Argon, carbon dioxide, oxygen, and helium are some of the most commonly used gases in welding applications. Consulting with a supplier like Metro Welding Supply Corporation will help ensure you select the right gases for your needs.

Setting Up a Micro-Bulk Gas System

Setting up a micro-bulk gas system involves selecting the right tank size and ensuring proper installation for easy gas access. Once the tank is installed, a delivery system will be set up to monitor usage and ensure consistent supply. Metro Welding Supply Corporation can assist with setting up these systems, ensuring a seamless transition from traditional cylinder systems.

Top Welding Equipment Maintenance Tips for Longevity and Optimal Performance

Regular Cleaning and Inspection of Welding Equipment

Welding equipment is prone to buildup from heat, metal deposits, and other debris. Regular cleaning ensures that your equipment remains in optimal condition, reducing downtime and extending the lifespan of your tools. Be sure to clean your welding nozzles, torch, and other key components after each use.

Calibration and Testing of Welding Machines

Calibration and testing of welding machines ensure that your equipment is functioning correctly. Regular calibration guarantees that welding machines are producing the right heat and power for the job, leading to better results and fewer welding defects.

The Importance of Protective Measures for Welding Tools and Equipment

Protective measures such as storage in a dry, temperature-controlled environment, as well as using covers to shield equipment from dust and dirt, can extend the lifespan of welding tools and prevent damage during periods of inactivity.

How Metro Welding Supply Corporation Supports Sustainable Welding Practices

Providing High-Quality Micro-Bulk Gases

Metro Welding Supply Corporation offers a range of micro-bulk gases tailored to the needs of various welding industries. By working with the company, businesses can reduce their environmental impact while enjoying a reliable and efficient gas supply.

Offering Expert Maintenance Services for Welding Equipment

Metro Welding Supply Corporation doesn't just supply gases – they also offer maintenance services to ensure that your welding equipment stays in top shape. Their team of experts can handle everything from cleaning and calibration to full equipment servicing.

Educational Resources for Sustainable Welding Practices

Through workshops, training programs, and expert advice, Metro Welding Supply Corporation helps businesses learn more about sustainable welding practices and how to integrate them into their operations.

Customer Benefits of Choosing Metro Welding Supply for Welding Solutions

Reliable Gas Supply and Delivery

Metro Welding Supply Corporation provides timely and reliable gas delivery services, ensuring that your business never experiences downtime due to gas shortages or delays.

Long-Term Customer Support and Technical Expertise

With a strong commitment to customer service, Metro Welding Supply Corporation offers ongoing support to help businesses navigate the challenges of sustainable welding.

Frequently Asked Questions (FAQs)

What is the difference between micro-bulk gases and traditional cylinder gases?

- Micro-bulk gases are delivered in larger quantities but are stored in smaller tanks, providing more flexibility, cost savings, and reliability compared to traditional gas cylinders.

Can micro-bulk gases reduce my welding costs?

- Yes, micro-bulk gases offer significant savings by eliminating the need for frequent cylinder replacements and minimizing delivery costs.

How can I maintain my welding equipment for maximum performance?

- Regular cleaning, calibration, and protective measures are essential to keep welding equipment in optimal working condition.

What are the environmental benefits of using micro-bulk gases in welding?

- Micro-bulk gases reduce the carbon footprint by minimizing waste and transportation emissions associated with traditional gas cylinder delivery.

How does Metro Welding Supply support sustainable welding practices?

- Metro Welding Supply Corporation supports sustainability by offering micro-bulk gases, expert equipment maintenance, and educational resources to help businesses reduce their environmental impact.

Are micro-bulk gases available for all types of welding applications?

- Yes, micro-bulk gases are suitable for various welding processes, including MIG, TIG, and flux-cored arc welding.

Conclusion: Embracing Sustainable Welding Practices with Metro Welding Supply Corporation

Incorporating micro-bulk gases into your welding operations can lead to significant benefits, including cost savings, improved performance, and a reduced environmental footprint. By partnering with Metro Welding Supply Corporation, you can ensure a reliable supply of gases while benefiting from their expertise in welding equipment maintenance and sustainable practices.

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660

Agency Contact Form

More Industry Tips, Tricks & Tools...

Industry Insights (i2)