Understanding Medical Laser Gases: Types, Uses, and Safety

Introduction to Medical Laser Gases

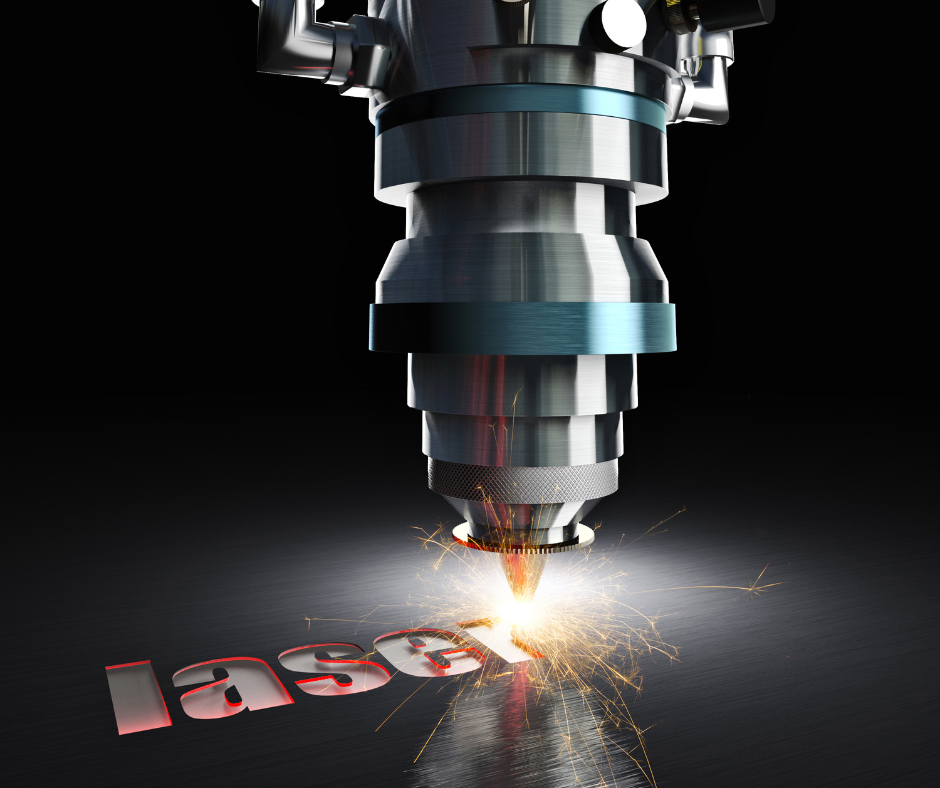

Medical lasers have revolutionized healthcare, providing precision and effectiveness in treatments ranging from surgery to cosmetic procedures. But did you know that medical laser gases play a critical role in the functionality of these lasers? These gases are essential for the operation, control, and safety of medical lasers. In this guide, we'll explore the various types of medical laser gases, their applications, and the important safety measures to consider.

What Are Medical Laser Gases?

Medical laser gases are specialized gases used in the operation of medical lasers. These gases either contribute to the laser medium itself or are used as assistive gases to enhance the laser's functionality. They are carefully selected based on their interaction with light and their ability to amplify the laser beam.

Types of Medical Laser Gases

There are several types of gases commonly used in medical lasers, each with specific applications:

- Carbon Dioxide (CO2)

- Widely used in surgical lasers.

- Excellent for cutting and vaporizing soft tissues.

- Helium-Neon (HeNe)

- Commonly used in alignment and low-power applications.

- Produces a visible red laser beam, ideal for precise targeting.

- Argon

- Used in ophthalmology and dermatology.

- Emits blue or green light, which is highly absorbed by blood and melanin.

- Krypton

- Similar to Argon but with a broader range of colors.

- Used in specialized ophthalmic procedures.

- Excimer Gases (e.g., Xenon Chloride, Krypton Fluoride)

- Used in eye surgery, particularly for LASIK.

- Produces ultraviolet light for precise tissue ablation.

- Nitrogen

- Utilized in dermatology for treating vascular lesions.

- Also used in laser-pumped dye lasers.

Applications of Medical Laser Gases

Medical laser gases are used in various healthcare applications, including:

- Surgical Procedures: CO2 lasers are common in surgeries for cutting and vaporizing tissues with minimal bleeding.

- Ophthalmology: Argon and Krypton lasers are used to treat retinal disorders and other eye conditions.

- Dermatology: Excimer and nitrogen lasers are used for skin resurfacing, treating vascular lesions, and removing tattoos.

- Cosmetic Procedures: Laser gases are essential in treatments like hair removal, skin tightening, and wrinkle reduction.

How Medical Laser Gases Work

Medical laser gases function by providing the medium through which the laser light is generated. For example, in a CO2 laser, the carbon dioxide gas is electrically excited, producing a beam of infrared light. This light is then focused and directed for surgical procedures. Other gases, like argon and krypton, produce light in the visible spectrum and are used where precision and specific absorption by tissues are required.

Safety Considerations for Medical Laser Gases

Handling medical laser gases requires strict safety protocols:

- Proper Storage: Medical laser gases should be stored in appropriate cylinders, in well-ventilated areas, and away from flammable materials.

- Gas Leak Detection: Regular checks for gas leaks are essential to prevent accidental exposure.

- Protective Equipment: Personnel should wear protective gear, including laser safety goggles, when operating lasers.

- Regulation Compliance: Ensure that the use of medical laser gases complies with all relevant regulations and standards.

- Ventilation: Adequate ventilation in laser treatment areas is crucial to prevent the buildup of any toxic or flammable gases.

Common Issues and Troubleshooting in Medical Laser Gas Systems

Even with proper maintenance, issues can arise in medical laser gas systems:

- Laser Beam Instability: Often caused by incorrect gas flow or pressure.

- Gas Leakage: Can lead to diminished laser performance and safety hazards.

- Contamination of Gas Lines: Leads to impurities in the laser beam, reducing effectiveness.

Maintaining Medical Laser Gas Systems

Regular maintenance is key to ensuring the safety and effectiveness of medical laser gas systems:

- Routine Inspections: Regularly check gas cylinders, connections, and laser equipment for signs of wear or damage.

- Gas Purity: Ensure that only high-purity gases are used to prevent contamination.

- Calibration: Regularly calibrate the laser system to ensure that the correct gas concentrations and flow rates are maintained.

Advantages of Using Medical Laser Gases

- Precision: Medical laser gases allow for highly precise surgical and therapeutic procedures.

- Minimized Tissue Damage: The use of specific gases helps focus the laser on targeted tissues, reducing collateral damage.

- Versatility: Different gases provide a range of laser wavelengths, making them suitable for various medical applications.

Challenges and Risks of Medical Laser Gases

While medical laser gases offer significant benefits, they also present certain challenges:

- Handling Risks: Gases like CO2 and argon require careful handling due to their pressurized and potentially hazardous nature.

- Cost: High-purity medical gases can be expensive, particularly in large-scale medical facilities.

- Regulatory Compliance: Strict regulations govern the use and storage of medical gases, requiring ongoing compliance efforts.

Future Trends in Medical Laser Gases

The future of medical laser gases is likely to see continued innovation:

- Enhanced Safety Protocols: Advances in safety technologies and protocols are expected to reduce risks associated with laser gases.

- New Gas Mixtures: Development of new gas mixtures that enhance laser efficiency and precision.

- Environmental Impact Reduction: Efforts to reduce the environmental impact of gas production and disposal in the medical industry.

Comparing Medical Laser Gases: Which Is Right for Your Practice?

Conclusion

Medical laser gases are an integral part of modern healthcare, enabling a wide range of precise and effective treatments. From CO2 for surgical procedures to argon for eye care, these gases help unlock the full potential of laser technology. By understanding the different types of medical laser gases, their applications, and the safety considerations involved, healthcare professionals can ensure they are using these powerful tools effectively and safely.

For over 80 years, Metro Welding Supply Corp has been the trusted partner for businesses across Southeast Michigan, delivering high-quality welding supplies, specialty gases, and exceptional customer service. Whether you’re in construction, manufacturing, or healthcare, we have the products and expertise to meet your needs. Our team is committed to providing reliable solutions that keep your operations running smoothly. Contact us today at 313-834-1660 or via email at sales@metrowelding.com to learn how we can support your business with the best in welding supplies and specialty gases.

FAQ's

What is the most common gas used in medical lasers?

Carbon dioxide (CO2) is one of the most common gases used in medical lasers, particularly for surgical applications.

Are medical laser gases dangerous?

While medical laser gases are safe when handled properly, they require strict safety measures to prevent risks such as gas leaks or exposure.

How often should medical laser gas systems be maintained?

Regular maintenance, including inspections and calibrations, should be performed at least quarterly or as recommended by the equipment manufacturer.

Can medical laser gases be used in all types of lasers?

No, the type of gas used depends on the specific laser system and its intended medical application.

What are the environmental concerns associated with medical laser gases?

The production and disposal of medical laser gases can have environmental impacts, which is why there is a growing focus on reducing these effects through sustainable practices.

Ready to work with Metro Welding Supply Corp.?

Let's connect! We’re here to help.

Send us a message and we’ll be in touch.

Or give us a call today at 313-834-1660

Agency Contact Form

We will get back to you as soon as possible

Please try again later

More Industry Tips, Tricks & Tools...

Industry Insights (i2)

Note: Always adhere to industry-specific safety guidelines and consult with professionals for proper handling, storage, and usage of pressurized gases.

Menu

Business Growth & Customer

Engagement Partners:

GAWDA – Industry Association →

www.gawda.org

Lead Monkey Marketing LLC – SEO & Digital Growth →

www.leadmonkeyllc.com

All Rights Reserved. Designed By Lead Monkey Marketing LLC